Prototype LEGO engine(1994)

Prototype LEGO engine(1994)

Prototype LEGO engine(1994)

Prototype LEGO engine(1994)

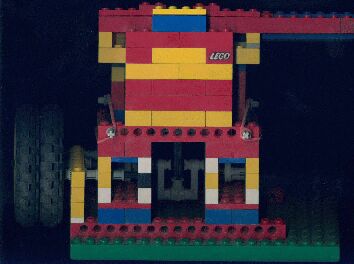

This is a side shot of the engine. You can see my vintage LEGO block

in the cylinder. I also used 2 of the Technic wheels from the Motorcycle

set for flywheels and some steering pieces in the crankshaft. On

either side of the cylinder, you can see the slider valves and the rubber

bands that act as low tension springs. The long piece going off to the

right of the picture is the air inlet tube.

This is a side shot of the engine. You can see my vintage LEGO block

in the cylinder. I also used 2 of the Technic wheels from the Motorcycle

set for flywheels and some steering pieces in the crankshaft. On

either side of the cylinder, you can see the slider valves and the rubber

bands that act as low tension springs. The long piece going off to the

right of the picture is the air inlet tube.

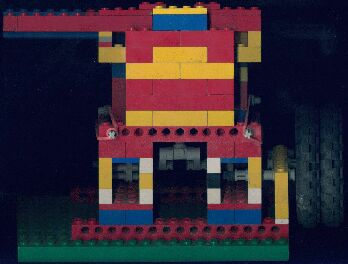

Here is the other side of the engine. You can see the crankshaft

setup a little bit better and notice how the slider valves are in a little

different position than in the previous photo.

Here is the other side of the engine. You can see the crankshaft

setup a little bit better and notice how the slider valves are in a little

different position than in the previous photo.

This is the

intake side of the engine. You can see the slider valve with rubber

band and the size of the air inlet tube in this shot. Sorry for the

shadow in the picture - I put the engine on the scanner instead of taking

an actual picture.

This is the

intake side of the engine. You can see the slider valve with rubber

band and the size of the air inlet tube in this shot. Sorry for the

shadow in the picture - I put the engine on the scanner instead of taking

an actual picture.

If you would like to see a cheesy still frame animation of this engine running, you can download the 460K zipped .avi file by clicking HERE.

The pictures on this page were created using an EasyPhoto ImageWave

scanner.

==================================================================================

Today I managed to successfully complete a 20

minute trial run of this engine. Compressed air was just way too

much for this engine to handle. It turns out that most of these LEGO

engines run best with an HVLP setup (High Volume Low Pressure) namely,

a wet/dry vac using the outlet side. I used some duct tape and taped

the output nozzle of my wet/dry vac to the intake port of the 1994 prototype

engine. Using a bench vise to hold the nozzle, I turned on the vaccuum,

spun the engine, and it ran continously for over 20 minutes until I shut

off the vaccuum.

I used trace amounts of silicon lubricant applied while the engine

was running to help it run smoother and reduce wear on the LEGO pieces.

Experimenting with the flywheels showed that using both wheels generated

the most power while using one wheel generated the most RPM's. The

engine generated enough torque to resist a mild yet firm touch of resistance

from my finger. A twin cylinder version would surely produce modest

power gains.

==================================================================================